Honeywell TDC-3000 System Structure and Features

Time:Oct 21,2025

In 1975, Honeywell introduced the TDC-2000, the world's first distributed control system. After years of continuous technological development, the TDC-3000 was launched in October 1983. This system adopted a Local Control Network (LCN), added a process control management layer, and the original TDC-2000 was converted to TDC-3000 BASIC. In 1988, the TDC-3000 (UCN) was introduced, adding new products such as the Universal Control Network (UCN), Universal Workstation (UWS), Process Management Station (PM), and the ST3000 intelligent transmitter, further enhancing the system's control capabilities, open communication network, and integrated information management.

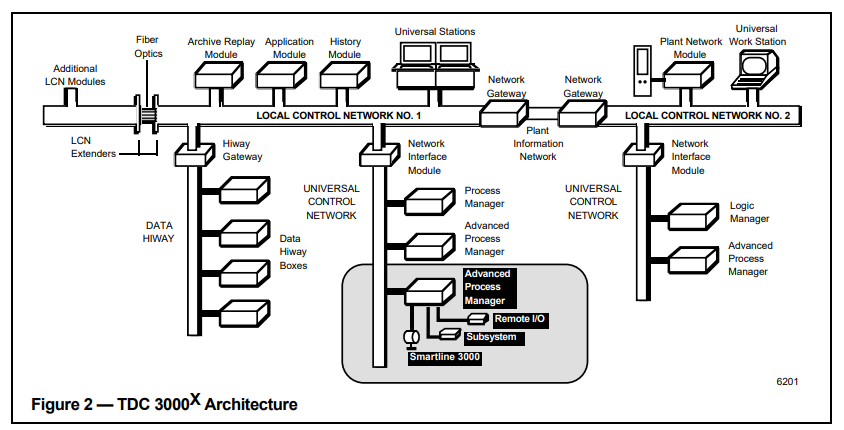

The TDC-3000 system consists of the LCN network and its modules, the UCN network and its management station, and the DHW communication channel and its equipment.

1. Local Control Network and Its Modules

The Local Control Network (LCN) and its connected modules consist of the LCN and the Universal Operation Station (US), the Universal Workstation (UWS), the History Module (HM), the Application Module (AM), the Network Interface Module (NIM), the High-Speed Channel Interface (HG), the Computer Interface (CG), and the Programmable Logic Controller Interface (PLCG). It mainly completes various functions required by users, such as system monitoring, operation, engineering management and maintenance; is used for advanced control and integrated information processing; provides connections with the process control network; and realizes communication, information processing and storage between modules on the LCN network.

(1) The Universal Operation Station (US) is the main human-machine interface of the TDC-3000 system. Through the US, operators and managers can monitor and control continuous and non-continuous production processes, complete signal alarms and alarm printing, trend display and printing, log and report printing, flow chart screen display and system status display. Engineers can complete network configuration, establish process databases and flow chart screens, and compile free reports and control programs. Maintenance personnel can use US to diagnose system faults, display system hardware status, and print fault information. (2) The Universal Work Station (UWS) is another human-machine interface of the TDC-3000 system. It has all the functions of US and is designed specifically for factory office management. (3) The History Module (HM) is the storage unit of the TDC-3000 system. It can store process alarms, operator status changes, operator information, system status information, system maintenance prompts, continuous process history data, etc. It also stores system files, CHECKPOINT files, and online maintenance information. (4) The Application Module (AM) is used to perform complex calculations and realize advanced, multi-variable control functions to improve process control and management levels. (5) The Network Interface Module (NIM), High Gateway (HG), and Computer Gateway (CG) are interfaces for data communication between the LCN and the UCN, the data highway DHW, and the host computer (such as DEC VAX, etc.). The LCN network can connect 64 modules, with a communication rate of 5Mbps and a length of 300m, with a maximum distance of up to 4.9km.

2. The Universal Control Network and its management station (UCN) are used to communicate with the process management station PM and the logical management station LM connected to it. It is a process network that realizes data acquisition and control functions. It is connected to the local control network (LCN) through the network interface module (NIM) to realize the monitoring, operation, information management and system maintenance functions required by users. (1) The Universal Control Network (UCN) is an open communication network that uses the IEEE 802.4 standard communication protocol and is compatible with ISO standards. It has a communication rate of 5Mbps, peer-to-peer communication, and token bus transmission. Redundant coaxial cables are used to support up to 32 redundant devices, allowing PMs and LMs on the network to share network data. 63 modules (32 redundant devices) can be connected to the UCN network, and the network distance is usually 300 m. (2) The Process Manager (PM) integrates the functions of a multi-function controller and a process interface unit, and has greater improvements and enhancements in speed, capacity, and functionality. It provides highly flexible input/output functions and powerful control functions for data monitoring and control, including a dedicated regulation control software package, fully centralized interlocking logic functions, and a process-oriented high-level control language (CL/PM). It can easily implement continuous control, logic control, sequential control, and batch control. The PM has a scan cycle of 0.75s. One PM can process 5,000 CL/PM statement programs. (3) The Advanced Process Manager (APM) is an improved product of the PM. Compared with the PM, it adds data points such as digital input event sequence (DICOE) processing, DEVICE management points, CL programs, and non-TDC-3000 device serial interface capabilities. Another major improvement is the enhancement of CL/APM functions. For example, the increase in device management points makes the management of discrete devices more flexible. The combination of composite digital point display and logic control functions under the same bit number allows operators to directly see the cause of the interlock. The serial interface capability of non-TDC-3000 devices allows the UPC 6000 process controller with serial communication capabilities to be directly connected to the APM and operated as an auxiliary system of the APM. (4) Logical Management Station (LM) The Logic Manager (LM) is a field management station for logic control, providing functions such as logic processing, ladder logic programming, logic program execution, and communication with modules in the UCN and LCN networks.

3. Data Highway and Devices

The DHW is the data highway of the TDC-3000 BASIC, used to connect units such as the Basic Control (BC), Enhanced Controller (EC), Multi-Function Controller (MC), Advanced Multi-Function Controller (AMC), Process Interface Unit (PIU), Data Highway Port (DHP), and Basic Operating Station (BOS), enabling production process control and data acquisition. It connects to the Local Control Network (LCN) via the Highway Port (HG) to provide user-required monitoring, operation, information management, and system maintenance functions. The DHW can connect to 63 modules (32 redundant devices), uses priority and interrogation control modes, has a communication range of 1500m, and a communication rate of 250Kbps. The DHW has been replaced by the UCN.

TDC-3000 System Features

1. Open System

The TDC-3000 system adopts IEEE 8012.4 and ISO 8802/4 international standards, based on the seven-layer protocol of the ISO/OSI Open Systems Interconnection Reference Model, enabling interconnection with non-Honeywell equipment.

2. Increasingly Hierarchical Control

The TDC-3000 system provides three levels of distributed control. The first is the process control level, which controls process terminal equipment based on field process control devices. The second is the advanced control level, which includes more complex control strategies and control calculations than the process control level and is commonly referred to as the plant level. The third is the highest control level, which provides technologies and methods for advanced calculations, such as computational simulation for complex control, process optimization control, and linear programming. This level is called the federated level. Engineers can utilize these control levels to achieve the most economical and efficient control and can also implement different levels of control through configuration. In addition, if a failure occurs at a higher level, the control configuration can be downgraded to the next level for control operation.

3. Wide Range of Data Acquisition and Control Functions

4. Process-Oriented Single Window: The TDC-3000 system utilizes the Universal Operation Station (US), a true process-oriented single window featuring universal data access, flexible coordination and customized operations, and a variety of display formats.

5. Integrated Factory Management and Control

6. Flexible System Scale Configuration and Easy Expansion

7. Safe, Reliable, and Easy Maintenance

The TDC-3000 system utilizes fault-tolerant technology in its overall design, allowing for errors in both hardware and software and incorporating error detection and correction components. When a module error occurs, it typically affects only the module in which it resides, with minimal or no impact on system operation. If a device fails, some of its capabilities or functions may be lost, but the system will continue to operate. The TDC-3000 system utilizes extensive redundancy technology. Furthermore, self-diagnostic and self-correction routines are widely used, along with standardized hardware and software. Much of the hardware is universally compatible, and each component is a best-fit replacement unit, enabling online repair.

8. Compatibility between New and Old Systems

The TDC-3000 system is fully compatible with the TDC-2000 system, allowing them to coexist within the same system, each becoming part of the overall system.

MORE BLOG

Shanghai International Entrepreneurs Advisory Meeting - ABB AI+Energy Synergy Solution

Honeywell TDC-3000 System Structure and Features

Basic Structure and Development Stages of a Distributed Control System

About Us

Topteng Technology Trading Co., Limited

Established in 2010, Topteng has been a supplier of industrial automation spare parts for decades. Specialized in PLC, DCS, ESD and TSl fields, we provide the best automation solutions.

Address:

Units 1503-1504, No. 96-2 Lujiang Road

Siming District

Xiamen City, Fujian Province 361001

China

Copyright © 2025 Topteng Technology Trading Co., Limited All Rights reserved.