Basic Structure and Development Stages of a Distributed Control System

Time:Oct 20,2025

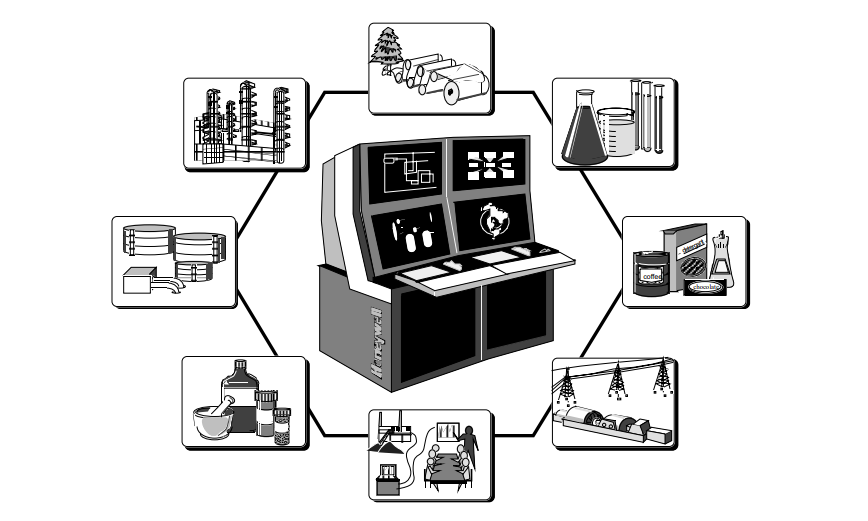

A distributed control system consists of three major components: distributed process control units (DCSs), centralized operations and management units (COMs), and communication systems.

Distributed process control units (DCSs) serve as the interface between the DCS and the production process and can be categorized by function as field control stations and data acquisition stations. Centralized operations and management units (COMs) serve as the interface between humans and the DCS and can be categorized by function as operator workstations, engineer workstations, and monitoring computers. The communication system is the core of the DCS, connecting all its components into a cohesive whole.

Therefore, the operator station, engineer station, monitoring computer, field control station, data acquisition station, and communication system are the most basic components of a DCS.

1. Operator Station. The operator station is the primary device used by operators to display, monitor, operate, control, and manage the production process, providing an excellent human-computer interface.

2. Engineer Station. The engineer station is used for offline DCS configuration and online system monitoring, control, and maintenance.

3. Monitoring Computer. The monitoring computer collects data from each unit in the system via a network and performs background calculations and optimization control based on mathematical models and optimal control indicators. It also provides comprehensive management of information across the entire system.

4. Field Control Station. The field control station directly connects to the production process through field instruments, collects process variable information, performs conversions and calculations, and generates control signals to drive on-site actuators, thereby controlling the production process. The field control station can autonomously complete loop control tasks, implementing functions such as feedback control, logic control, sequential control, and batch control.

5. Data Acquisition Station. The data acquisition station collects and preprocesses non-controlled process variables and further processes real-time data. It provides data to the operation station for process monitoring and information storage, and provides auxiliary data and information for control loop operations.

6. Communication System. The communication system connects the various components of the DCS, transmitting data, instructions, and other information between workstations, ensuring coordinated operation of the entire system.

The development of distributed control systems has generally progressed through four periods.

1. 1975-1980 marked the initial development period. The technical focus of DCS during this period was decentralized control, overcoming the critical weakness of centralized computer control systems, which often suffer from high concentrations of risk, and enhancing reliability. Typical products include Honeywell's TDC-2000, Foxboro's SPECTRUM, Yokogawa's CENTUM, and Siemens' TELEPERMM.

2. 1980-1985 marked the mature development period. The technical focus of DCS during this period was achieving integrated management of system-wide information. To achieve this, advanced local network technology was essential to strengthen communication systems. Representative products include Honeywell's TDC-3000, Yokogawa's CENTUM, and Taylor's MOD-300.

3. 1985-1990 marked the expansion period. The primary structural change in DCS during this expansion period was the adoption of standardized, open communication protocols for local networks. For example, it uses the Manufacturing Automation Protocol (MAP) based on the Open Systems Interconnection Reference Model, is compatible with MA, or is itself a real-time MAP local network. Other units have undergone significant improvements in both hardware and software, but the basic system components remain largely unchanged. Another characteristic of the extended DCS is the extension of system intelligence to the field, with the introduction of smart transmitters and fieldbus technology. Smart transmitters have digital communication capabilities and connect to process control stations or local network nodes via the fieldbus. Operations such as zeroing, spanning, configuration, automatic calibration, automatic diagnosis, and automatic troubleshooting can be performed on the smart transmitters in the field from the control room or at the node workstation. Representative products include Honeywell's TDC-3000/PM, YOKOGAWA's CENTUM-XL, Foxboro's I/AS, and Bailey Control's INFI-90.

4. Since the 1990s, with the rapid development of computer, communication, and control technologies, especially network technology, and the increasing demand for control and management, new distributed control systems (DCs) have emerged, characterized by integrated management and control. These systems utilize a client/server architecture, adding a factory management information network (Intranet) and Internet connectivity. Typical products include Honeywell's TPS system, Yokogawa's CENTUM CS system, and Foxboro's I/A S5051 series control systems.

MORE BLOG

Shanghai International Entrepreneurs Advisory Meeting - ABB AI+Energy Synergy Solution

Honeywell TDC-3000 System Structure and Features

Basic Structure and Development Stages of a Distributed Control System

About Us

Topteng Technology Trading Co., Limited

Established in 2010, Topteng has been a supplier of industrial automation spare parts for decades. Specialized in PLC, DCS, ESD and TSl fields, we provide the best automation solutions.

Address:

Units 1503-1504, No. 96-2 Lujiang Road

Siming District

Xiamen City, Fujian Province 361001

China

Copyright © 2025 Topteng Technology Trading Co., Limited All Rights reserved.