How to position and figure out the PLC working failure in the site?

Time:Oct 14,2025

If a PLC module fails to function properly after being powered on, how can we quickly identify and resolve the module's problem?

First, it's important to understand that the module inspection strategy should be: external first, internal second; hardware first, software second; power first, signal second.

The first stage involves a basic inspection of the module's exterior.

The first priority is the module's power connection.

1. Is the power supply voltage within the rated range?

2. Are the positive and negative poles connected incorrectly?

3. Is the power supply module sufficient to power all modules (CPU, expansion modules, loads, etc.)?

4. If fuses are installed on the main unit and expansion modules, are they blown?

The next step is to inspect the module's installation and connections. This includes ensuring that all modules are securely attached to the DIN rails; ensuring that the power, I/O, and communication cables are securely plugged in; and ensuring that important terminals, such as the power supply, are tightened.

Then, observe the module's indicator lights.

1. PWR / POWER LED off/flashes -- No power, incorrect power connection, low voltage, or damage to the module's internal power circuit.

2. RUN / RUNNING off/flashes -- The CPU is in STOP state, a hardware fault, or a program error. Alternatively, the CPU may be booting up, in debug mode, or experiencing a recoverable error.

3. ERR / ERROR / SF off/flashes -- Hardware configuration error, fatal program error, communication interruption, etc.

4. I/O or COM LED off -- Communication interruption or module failure.

The second stage requires checking the module's hardware and configuration. This is the most common and primary reason for most modules not functioning properly.

1. Configuration discrepancies: In the programming software, the hardware model, version number, and order number set must be identical to the actual module in the rack. No letters or version numbers should differ. Is the module installed in the correct slot? -- Carefully verify the hardware configuration and re-download the correct configuration to the PLC.

2. Firmware version mismatch: For example, the firmware version of the CPU or functional module is too old to support the new configuration or instructions. -- Perform a firmware upgrade.

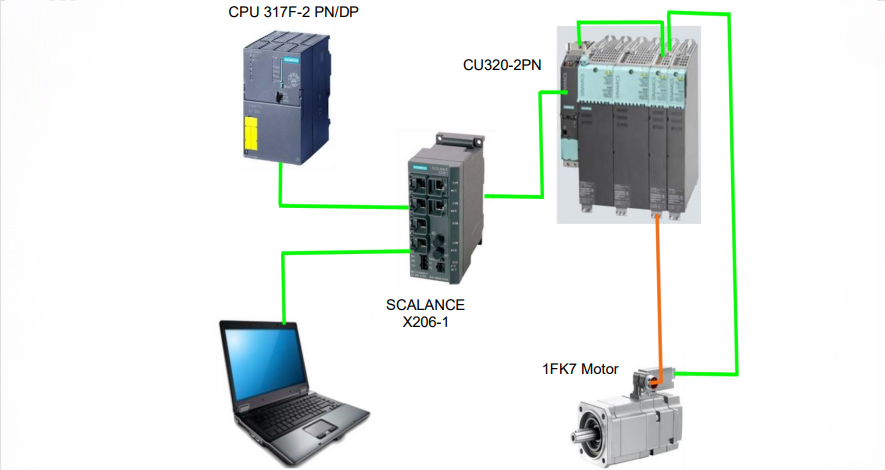

3. In a multi-master system (such as Profibus or Ethernet/IP), are there any conflicts in the device station address or IP address? -- All devices on the network must have the same address.

4. Communication settings: Are parameters such as baud rate, data bits, stop bits, and parity consistent with those of the communication partner device? Are the IP address, subnet mask, and gateway settings correct?

The third stage involves checking the software and program associated with the module.

1. The program may contain a stop instruction or a fatal program error, causing the CPU to enter the STOP state immediately. -- Connect to the PLC through the programming software and check the diagnostic buffer for the specific cause and location of the CPU stop.

2. The user program execution cycle is too long, exceeding the CPU cycle time monitoring (watchdog) setting. -- Optimize the program structure, reduce the cycle scan time, or appropriately increase the watchdog time.

3. The CPU contains an empty program, or the program failed to download successfully.

The final stage requires troubleshooting the module's external environment and internal hardware. For example:

1. Wiring errors: output short circuit; input voltage too high; sensor/actuator overload.

2. Electromagnetic interference: Improper wiring (such as running power and signal cables in the same cable tray) can cause strong electromagnetic interference, disrupting communication.

3. Physical hardware damage: If the problem persists after completing all the above troubleshooting steps, the module itself is likely damaged.

MORE BLOG

We've Moved! A New Chapter Begins

How to position and figure out the PLC working failure in the site?

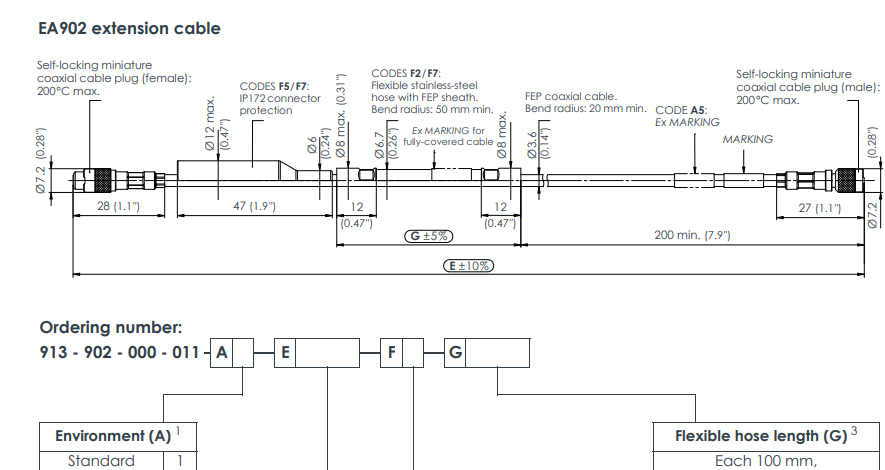

Why Choose the EA902 Extension Cable for Your Electrical Needs?

About Us

Topteng Technology Trading Co., Limited

Established in 2010, Topteng has been a supplier of industrial automation spare parts for decades. Specialized in PLC, DCS, ESD and TSl fields, we provide the best automation solutions.

Address:

Units 1503-1504, No. 96-2 Lujiang Road

Siming District

Xiamen City, Fujian Province 361001

China

Copyright © 2025 Topteng Technology Trading Co., Limited All Rights reserved.