Unlocking Precision: The Role of Vibro Meter AE119 in Vibration Sensing

Time:Oct 03,2025

Unlocking Precision: The Role of Vibro Meter AE119 in Vibration Sensing

Table of Contents

- 1. Introduction to Vibration Sensing

- 2. Overview of Vibro Meter AE119

- 3. Key Features of Vibro Meter AE119

- 4. Applications of Vibro Meter AE119 in Various Industries

- 5. Advantages of Using Vibro Meter AE119 in Vibration Analysis

- 6. Comparison with Other Vibration Sensors

- 7. Real-World Case Studies Demonstrating AE119’s Effectiveness

- 8. Future Trends in Vibration Sensing Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Vibration Sensing

In today's fast-paced industrial landscape, **vibration sensing** has become an indispensable tool for ensuring the operational integrity of machinery and infrastructure. With increasing demands for efficiency and reliability, understanding the nuances of vibration monitoring is crucial. The rise of sophisticated sensors has made it possible to capture minute changes in vibration patterns, which can be indicative of machinery problems, enabling timely interventions. This article delves into the Vibro Meter AE119, a cutting-edge solution in vibration sensing technology.

2. Overview of Vibro Meter AE119

The **Vibro Meter AE119** is a top-tier vibration sensor designed to measure the vibration of machinery and structures accurately. With its advanced technology and robust design, it stands out in the field of vibration analysis. The AE119 excels in both sensitivity and precision, making it a preferred choice for industries that prioritize operational safety and efficiency. Its compact form factor and ease of integration further enhance its appeal among engineers and technicians.

2.1 Design and Build Quality

Crafted from high-grade materials, the AE119 is engineered to withstand harsh industrial environments. Its durable exterior protects the sensitive internal components, ensuring longevity and reliability even in the most demanding settings. The sensor's compact design does not compromise its performance; rather, it allows for versatility in installation.

2.2 Technology Behind AE119

The AE119 operates on advanced piezoelectric technology, which enables it to convert mechanical vibrations into electrical signals. This conversion process ensures that even the slightest vibrations are detected, allowing for detailed analysis and comprehensive monitoring of equipment performance.

3. Key Features of Vibro Meter AE119

The **Vibro Meter AE119** comes equipped with a myriad of features that enhance its functionality and user experience:

3.1 High Sensitivity and Range

With an impressive sensitivity range, the AE119 is capable of detecting vibrations from low-frequency machinery to high-frequency impacts. This versatility makes it suitable for various applications across different sectors.

3.2 Robust Data Output

The AE119 provides real-time data output, ensuring that engineers have immediate access to critical information. This capability is vital for making informed decisions swiftly, particularly in maintenance scenarios.

3.3 Easy Integration and Compatibility

Designed to be user-friendly, the AE119 can be seamlessly integrated into existing systems. Its compatibility with various monitoring software streamlines the process of data analysis, making it accessible even to those with limited technical expertise.

3.4 Comprehensive Diagnostic Capabilities

The sensor offers comprehensive diagnostic features that allow for deep insights into machinery conditions. This functionality aids in predictive maintenance strategies, reducing downtime and operational costs.

4. Applications of Vibro Meter AE119 in Various Industries

The versatility of the Vibro Meter AE119 enables its application across multiple sectors:

4.1 Manufacturing

In manufacturing, the AE119 is used to monitor the health of machinery, ensuring that equipment operates within safe vibration limits. Early detection of anomalies can prevent catastrophic failures.

4.2 Aerospace

The aerospace sector relies on the AE119 for precise monitoring of aircraft components. Its accuracy ensures that safety standards are upheld, and maintenance schedules are optimized.

4.3 Automotive

Automotive manufacturers utilize the AE119 to conduct vibration testing on engines and other components, ensuring that performance meets stringent industry standards.

4.4 Energy Production

In energy production, particularly in wind and solar industries, the AE119 is instrumental in monitoring turbine vibrations, contributing to enhanced operational efficiency and safety.

5. Advantages of Using Vibro Meter AE119 in Vibration Analysis

Utilizing the **Vibro Meter AE119** offers numerous advantages that can significantly improve operational processes:

5.1 Enhanced Operational Safety

By providing precise vibration measurements, the AE119 helps identify potential hazards before they escalate into serious issues, thereby enhancing workplace safety.

5.2 Improved Maintenance Efficiency

The real-time data output allows for timely interventions, ensuring that maintenance can be performed before equipment fails, thus reducing downtime and maintenance costs.

5.3 Cost-Effectiveness

Investing in the AE119 can lead to overall cost savings through reduced downtime, fewer emergency repairs, and longer equipment lifespan, making it a cost-effective solution for vibration monitoring.

5.4 User-Friendly Interface

The AE119 features an intuitive interface, making it easy for technicians to operate and analyze data, even if they are not highly trained in vibration analysis.

6. Comparison with Other Vibration Sensors

When comparing the Vibro Meter AE119 with other vibration sensors in the market, several key differentiators stand out:

6.1 Precision

While many sensors offer good sensitivity, the AE119 provides unparalleled precision, making it the preferred choice for industries where minute differences in vibration can signal significant problems.

6.2 Durability

Though many sensors claim to be durable, the AE119's robust construction ensures that it can withstand industrial wear and tear far better than its competitors.

6.3 Data Analysis Capabilities

Unlike basic vibration sensors that primarily provide raw data, the AE119 offers comprehensive analysis features, allowing for deeper insights into equipment performance.

7. Real-World Case Studies Demonstrating AE119’s Effectiveness

Several organizations have successfully integrated the Vibro Meter AE119 into their operations, resulting in notable improvements:

7.1 Automotive Manufacturer Case Study

An automotive manufacturer employed the AE119 to monitor engine vibrations, which led to early detection of potential failures. This proactive approach reduced their maintenance costs by 30%.

7.2 Aerospace Facility Case Study

A leading aerospace facility used the AE119 to enhance their vibration analysis processes, which resulted in improved safety compliance and operational efficiency, reducing inspection times by 25%.

8. Future Trends in Vibration Sensing Technology

As technology advances, the field of vibration sensing is expected to evolve significantly. Potential future trends include:

8.1 Integration with IoT

The integration of vibration sensors with **Internet of Things (IoT)** platforms will allow for more comprehensive data collection and analysis, enabling predictive maintenance strategies to become more refined and accurate.

8.2 Continued Miniaturization

As technology progresses, we can expect further miniaturization of vibration sensors, allowing for even more versatile applications without compromising performance.

8.3 Advanced Machine Learning Algorithms

The adoption of machine learning algorithms in vibration analysis will enhance the ability to predict failures and optimize maintenance schedules, leading to smarter operational decisions.

9. Frequently Asked Questions

9.1 What types of vibrations can the AE119 measure?

The AE119 can measure a wide range of vibrations, from low-frequency oscillations in large machinery to high-frequency impacts in delicate components.

9.2 How is the Vibro Meter AE119 installed?

The AE119 features a straightforward installation process, typically involving mounting the sensor in a predetermined location and connecting it to the monitoring system.

9.3 Can the AE119 integrate with existing monitoring systems?

Yes, the AE119 is designed to be compatible with various existing monitoring systems, facilitating easy integration without the need for significant overhauls.

9.4 What industries benefit the most from using the AE119?

The AE119 is beneficial across a range of industries, including manufacturing, aerospace, automotive, and energy production, among others.

9.5 How often should the AE119 be calibrated?

Regular calibration of the AE119 is recommended, typically once a year or as specified by the manufacturer, to maintain optimal performance and accuracy.

10. Conclusion

The **Vibro Meter AE119** represents a significant advancement in vibration sensing technology, offering unparalleled precision, durability, and user-friendliness. Its integration into various industrial applications has demonstrated substantial benefits in operational safety, maintenance efficiency, and cost savings. As industries continue to evolve, adopting sophisticated sensors like the AE119 will be key to maintaining competitive advantages. By embracing this technology, organizations can unlock new levels of operational excellence and reliability in their processes.

MORE BLOG

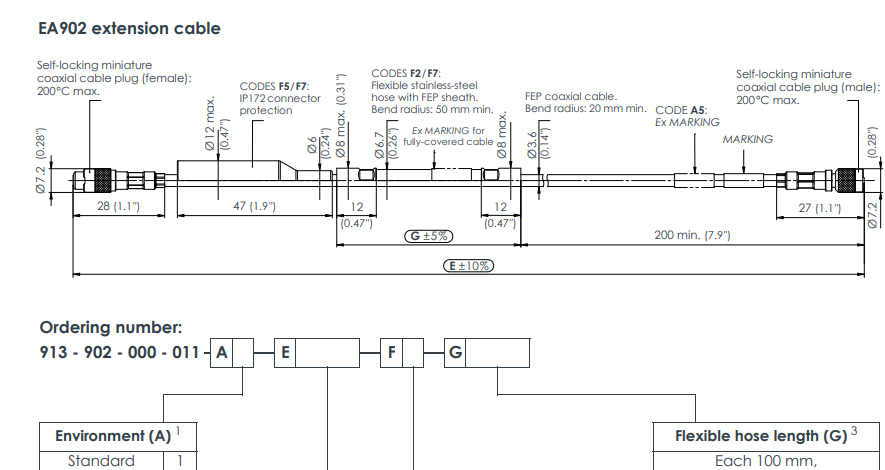

Why Choose the EA902 Extension Cable for Your Electrical Needs?

Understanding the CV213 Velocity Transducer: Applications and Benefits in Speed Measurement

Unlocking Precision: The Role of Vibro Meter AE119 in Vibration Sensing

About Us

Topteng Technology Trading Co., Limited

Established in 2010, Topteng has been a supplier of industrial automation spare parts for decades. Specialized in PLC, DCS, ESD and TSl fields, we provide the best automation solutions.

Address:

Unit 1904, No.96-2 Lujiang Road, Siming District, Xiamen city, 361001, Fujian, China.

Copyright © 2025 Topteng Technology Trading Co., Limited All Rights reserved.